Within the dynamic world of film production, certain innovations stand out for their profound impact on the industry’s operational standards. Among these, the Cardellini Clamp, designed and invented by Steve Cardellini in 1992, has become an indispensable tool across film sets worldwide.

Invention Born from Necessity

Steve Cardellini, with years of invaluable experience as a key grip, saw a gap in the toolkit available to film industry professionals. The existing clamping solutions were often limited in flexibility and functionality, particularly regarding the parallel alignment of jaw faces during use. Recognizing the potential for improvement, Cardellini set out to design a clamp that would address these limitations and meet the diverse needs of film production crews.

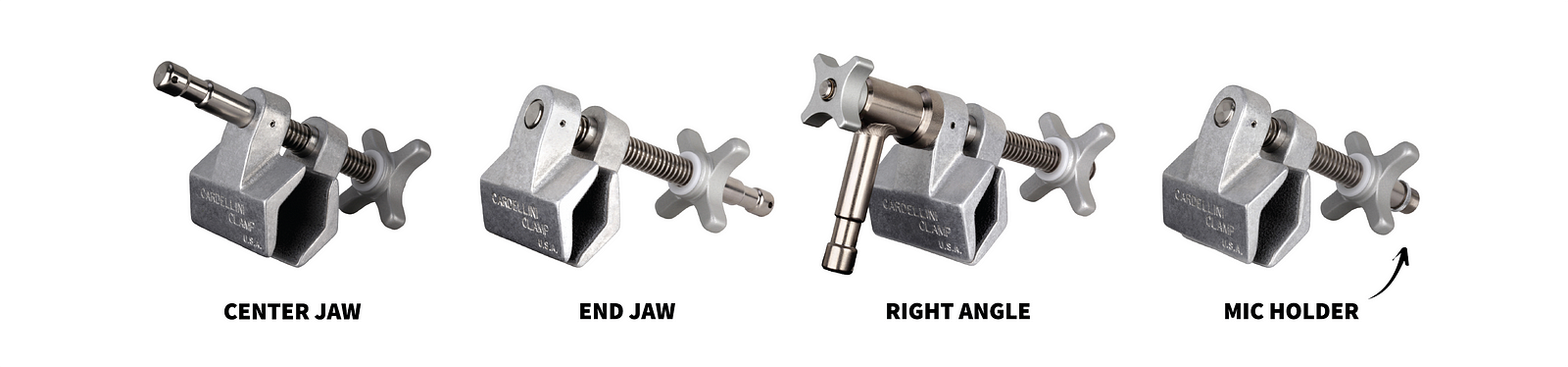

In 1992, Steve Cardellini introduced the Cardellini Clamp, a breakthrough in grip technology. The clamp’s patented two-angled jaw design was revolutionary, allowing for a solid grip on virtually any surface. This feature, coupled with the clamp’s versatility and durability, quickly established the Cardellini Clamp as the industry standard for film production equipment.

The essence of the Cardellini Clamp’s design lies in its unparalleled versatility. Its ability to securely attach to a wide array of surfaces and objects made it an immediate favorite among film professionals. Whether for mounting lighting equipment, securing camera rigs, or facilitating complex set designs, the Cardellini Clamp proved to be the perfect solution for an extensive range of applications.

Beyond its adaptability, the Cardellini Clamp is celebrated for its robust construction. Crafted to withstand the rigors of film production environments, it exemplifies durability. This reliability, paired with its solid grip, ensures that the Cardellini Clamp remains a mainstay in the industry, trusted by professionals to perform under the most demanding circumstances.

Matthews Studio Equipment, one of the largest global grip equipment manufacturers, recognized the ingenuity and widespread utility of Steve Cardellini’s design early on. In a move that both acknowledged the innovation of the Cardellini Clamp and sought to adapt its versatility to their own product line, Matthews licensed the design to create the Matthellini Clamp. This collaboration expanded the availability of this essential tool, incorporating the original’s patented two-angled jaw design and versatility into Matthews’ robust catalog of grip equipment. The Matthellini Clamp, akin to its predecessor, offers solid grip and adaptability, but under the Matthews brand, it further solidifies the legacy of Steve Cardellini’s original invention across the industry, ensuring that crews worldwide have access to this indispensable tool for a myriad of production needs.

Tips & Tricks from Cardellini Company

What is the best way to apply Cardellini Clamps?

The best way to apply the clamp is to hold the jaws closed on the object you want to clamp while spinning down the knob and tightening it. This works better than trying to close the jaws by turning the knob.

Is it possible to over-tighten the Cardellini clamp?

Yes — like any clamp, this one can be damaged by over-tightening. This is especially true if the clamp is applied where only the outside edges of the jaws are contacting the object being clamped. In this type of application, over-tightening will cause the sliding jaw to bind on the shaft, and could even bend the shaft.

If you choose to apply the clamp in this way, use the minimum amount of pressure necessary to safely secure the clamp; and never use tools to tighten the clamp.

What weight is this Cardellini clamp rated for?

This clamp is rated at 20 pounds. A securely attached clamp will support any lamp up to 20lbs that is mounted directly to the baby pin of the clamp. In situations where you are reaching out from the clamp and supporting a load on an offset arm or c-stand arm, you’ll need to determine safe load limits for each application.

What is the best way to remove the Cardellini clamp if it’s sticking?

If, when removing the clamp, you find the sliding jaw bound on the shaft, loosen the knob just a couple of turns, then wrap your fingers around the shaft and use your thumbs to pull the back end of the jaw toward the knob.

If this doesn’t work, a light tap on the back end of the sliding jaw will free it. Should the sliding jaw stick on the shaft after the clamp has been closed and stored, simply rotate the jaw to free it.

Today, the Cardellini Clamp and its accessories continue to be pivotal for professionals around the globe. The clamp embodies the ideal blend of functionality and reliability, attributes that stem directly from Steve Cardellini’s experience and ingenuity.

Shop The Grip Blog on The Grip Store

Hear more about Steve’s story on the Crew Call Podcast